| Status : Upcoming | Report Code : VRCH2047 | Industry : Chemicals & Materials | Available Format :

|

Global Industrial Gaskets Market – Analysis and Forecast (2025-2030)

Industry Insights by Material (Semi-Metallic, Non-Metallic, Metallic), by Product Type (Soft Gasket, Spiral Wound Gasket, Ring Joint Gasket), by End-User (Refineries, Power Generation, Chemical Processing) and by Geography (North America, Europe, Asia-Pacific, Middle East, and Rest of the World)

Industry Overview

Gasket is a mechanical seal that are used to fill the space between two or more than two mating surfaces. It is used to prevent leakage from the joined objects when they are under compression. It is commonly produced from sheet materials by cutting. Gaskets are generally made from flat materials which include a sheet, from rubber, paper, silicone, cork, felt, metal, nitrile rubber, fiberglass, and others. The industrial gaskets market is anticipated to register a good growth during the forecast period. This is attributed to its wide application in different end-user industries including power, oil and gas, chemicals, and others.

Industrial Gaskets Market Segmentation

Insight by Material

On the basis of material, the industrial gaskets market is classified into semi-metallic, non-metallic, and metallic. Of all these, semi-metallic material category is expected to dominate the market in the coming years. Semi-metallic gaskets are utilized by various end-user industries, as off the assembly they provide enhanced tightness with low overall load as compared to other type of gaskets. However, during the forecast period, non-metallic material category is anticipated to grow at the highest CAGR.

Insight by Product Type

Based on product type, the industrial gaskets market is categorized into soft gasket, spiral wound gasket, and ring joint gasket. Soft gaskets are the most dominant product type category, as it is the most preferred product type in various end-user industries which includes processing industry and others. This is attributed to the low-cost advantage it offers as compared to other gaskets.

Insight by End-User

On the basis of end-user, the industrial gaskets market is segmented into refineries, power generation, chemical processing, and others. The refineries end-user segment is anticipated to hold the largest share in the market in the coming years. This segment is projected to register the fastest growth in the market. This is attributed to the growth of the commercial application and increasing use of these gaskets in high temperature and pressure applications in refineries.

Global Industrial Gaskets Market Report Coverage

|

Report Metric |

Details |

|

Historical Period |

2018 - 2023 |

|

Base Year Considered |

2024 |

|

Forecast Period |

2025 - 2030 |

|

Market Size in 2024 |

U.S.D. xx Billion |

|

Revenue Forecast in 2030 |

U.S.D. xx Billion |

|

Growth Rate |

xx% |

|

Segments Covered in the Report |

By Material, By Product Type, and By End-User |

|

Report Scope |

Market Trends, Drivers, and Restraints; Revenue Estimation and Forecast; Segmentation Analysis; Impact of COVID-19; Companies’ Strategic Developments; Market Share Analysis of Key Players; Company Profiling |

|

Regions Covered in the Report |

North America, Europe, Asia-Pacific, Middle East, and Rest of the World |

Industry Dynamics

Industrial Gaskets Market Growth Drivers

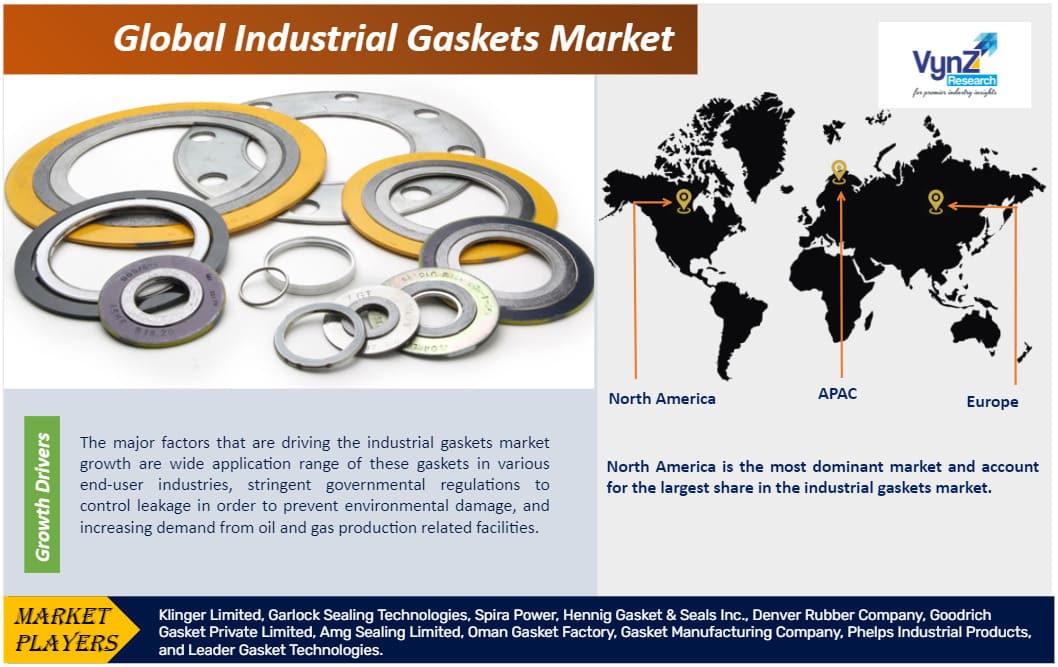

The major factors that are driving the industrial gaskets market growth are wide application range of these gaskets in various end-user industries, stringent governmental regulations to control leakage in order to prevent environmental damage, and increasing demand from oil and gas production related facilities. The application of these gaskets are increasing in various industries due to its superior properties such as, their resistance to chemicals, alkaline, acids, and others; resistance to extreme temperature; resistance to extreme pressure; resistance to withstand different environments, and others, resulting in driving the industrial gaskets market growth.

Industrial Gaskets Market Challenges

The major challenge identified in the market is the volatility of raw material prices. The principal raw materials required are mild steel sheet, asbestos sheet, and copper sheet. The material cost depends on the number of factors which includes material formulation, material production, material quality, material availability, and others. Hence, the fluctuating cost of raw material is one of the major challenges the industrial gaskets market is facing.

Industrial Gaskets Market Industry Ecosystem

The players in the industrial gaskets market are adopting organic and inorganic growth strategies to strengthen their position and to expand their market share. The manufacturers are investing heavily on research and development to enhance their product portfolio and to gain competitive edge in the market.

Recent Developments By the Key Players

The UK Gasket & Sealing Association (UKGSA) has announced several developments, including new factory moves, member additions, and fundraising efforts.

Leader Gasket Technologies has recently introduced LeaderTHERM NXT, an innovative gasket material designed for extreme temperature applications. This material is particularly suitable for industries such as power generation, gas boilers, and NOx-containing applications. It offers exceptional temperature resistance, low leakage, and minimal loss of gasket seating stress, outperforming existing materials in thermal cycling leakage tests.

Industrial Gaskets Market Geographic Overview

Globally, North America is the most dominant market and account for the largest share in the industrial gaskets market. The growth of the region’s market is mainly attributed to the growing demand of gaskets in end-user industries such as power, chemical, oil and gas, and other industries. However, during the forecast period, the Asia-Pacific is projected to register the fastest growth in the market, owing to the increasing power production in the region in order to meet the increasing power demand.

Industrial Gaskets Market Competitive Insight

- Klinger Limited

- Garlock Sealing Technologies

- Spira Power

- Hennig Gasket & Seals Inc.

- Denver Rubber Company

- Goodrich Gasket Private Limited

- Amg Sealing Limited

- Oman Gasket Factory

- Gasket Manufacturing Company

- Phelps Industrial Products

- Leader Gasket Technologies

Frequently Asked Questions

Purchase Options

Latest Report

Research Methodology

- Desk Research / Pilot Interviews

- Build Market Size Model

- Research and Analysis

- Final Deliverabvle

Connect With Our Sales Team

- Toll-Free: 1 888 253 3960

- Phone: +91 9960 288 381

- Email: enquiry@vynzresearch.com

Industrial Gaskets Market