Industry Overview

Metal injection molding is a metalworking process, where fine-powdered metal is mixed with binder material to produce feedstock. This feedstock then shaped and solidified using injection molding process. This process allow high volume and complex parts to be shaped at one go in a single step. The metal injection molding market is witnessing a decent growth in the last few years and anticipated to register a significant growth during the forecast period. This is attributed to the increasing demand of complex metal injection molded parts from different end-user industries including automotive, electronics, industrial, consumer products, and others.

Metal Injection Molding Market Segmentation

Insight by Material Type

Based on material type, the metal injection molding market is segmented into stainless steel, low alloy steel, soft magnetic material, and others. Other material type includes tool steel, tungsten, and titanium. Among all these, stainless steel is anticipated to dominate the market by registering the highest CAGR in the coming years. Stainless steel is preferred in the market due to various advantages it offers in terms of superior properties such as high corrosion resistance, excellent elongation and ductility, and others. Parts made from stainless steel are widely used in marine, food, and medical industry.

Insight by End-User

On the basis of end-user, the metal injection molding market is categorized into electrical and electronics, automotive, consumer, industrial, medical and orthodontics, firearms and defense, and others. During the forecast period, the electrical and electronics segment is projected to register the highest growth in the metal injection molding market, owing to the increasing demand of small and complex parts in the industry along with the rising demand for miniaturization of electronics devices. The common application of the process in electronics and electric appliances are in sensors, components in ovens or dishwashers, plug connectors in kitchenware, and others.

Global Metal Injection Molding Market Report Coverage

|

Report Metric

|

Details

|

|

Historical Period

|

2018 - 2023

|

|

Base Year Considered

|

2024

|

|

Forecast Period

|

2025 - 2030

|

|

Market Size in 2024

|

U.S.D. xx Billion

|

|

Revenue Forecast in 2030

|

U.S.D. xx Billion

|

|

Growth Rate

|

xx%

|

|

Segments Covered in the Report

|

By Material Type, and By End-User

|

|

Report Scope

|

Market Trends, Drivers, and Restraints; Revenue Estimation and Forecast; Segmentation Analysis; Impact of COVID-19; Companies’ Strategic Developments; Market Share Analysis of Key Players; Company Profiling

|

|

Regions Covered in the Report

|

North America, Europe, Asia-Pacific, Middle East, and Rest of the World

|

Industry Dynamics

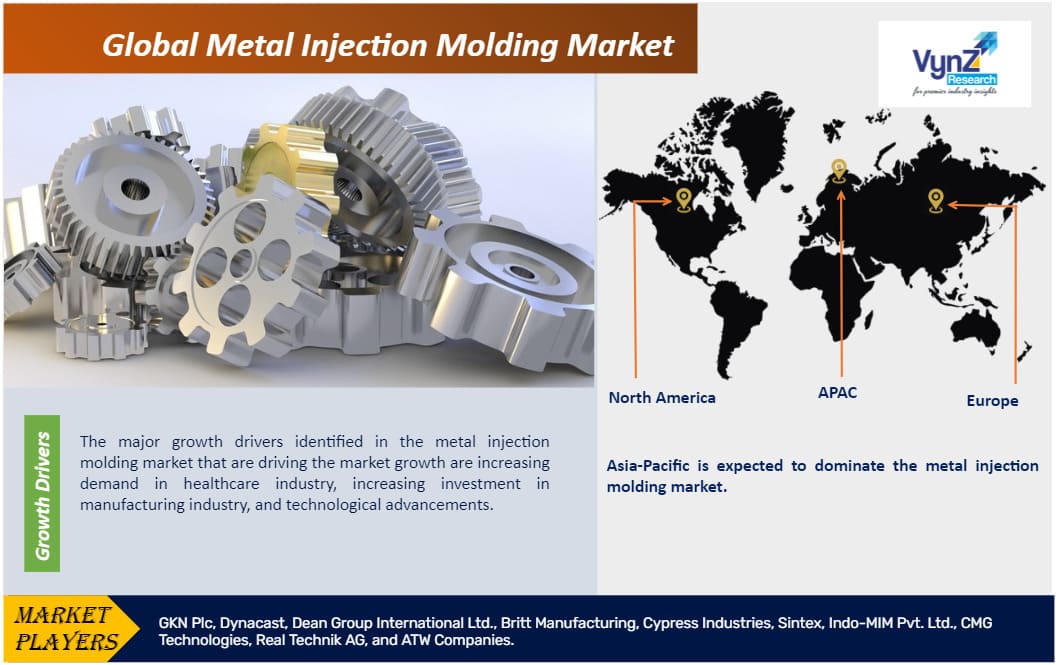

The major growth drivers identified in the metal injection molding market that are driving the market growth are increasing demand in healthcare industry, increasing investment in manufacturing industry, and technological advancements. The process is increasingly become popular in the medical and healthcare industry, owing to its ability to produce high volume of precision components. One of the most popular applications of the process is in keyhole surgery, devices that are used to manage diabetes, implantable devices, fracture, and other applications. Also, this is the much cheaper option as compared to conventional fabrication methods; hence the demand is expected to increase in the coming years, driving the market growth.

The major challenge identified in the metal injection molding market is that the process is expensive for small production capacities. The parts that are one to one manufactured using this process are always be more expensive as compared to traditional process which is expected to hinder the market growth. However, the productions in large volume batches are always cost-effective using this process.

Metal Injection Molding Market Industry Ecosystem

The metal injection molding is a four step process comprises of preparation of feedstock (metal powders and a thermoplastic binder), injection molding, binder removal, and sintering (elimination of most of the pore volume formerly occupied by the binder). For few applications which include automotive, medical and aerospace sectors, hot isostatic pressing (HIP) can be used to remove any residual porosity.

Recent Developments By the Key Players

HP Inc has partnered with Metal Injection Molding (MIM) company Indo-MIM to mass produce metal 3D parts in India.

Computer Modelling Group Ltd. and Kongsberg Digital and CMG have launched CO2LINK, a transformative simulator coupling that streamlines CO2 injection and storage processes.

Metal Injection Molding Market Geographic Overview

Globally, Asia-Pacific is expected to dominate the metal injection molding market, owing to the increasing demand from automotive industry along with the rising demand of miniaturization of consumer electronics for complex and small metal injection molded parts. Additionally, rapid industrialization and technological advancement are also expected to fuel the market growth in the coming years.

Metal Injection Molding Market Competitive Insight

Various companies operating in the metal injection molding industry are undertaking strategic initiatives to gain a competitive edge, which is likely to drive investments in the market over the forecast period.