| Status : Published | Published On : Dec, 2023 | Report Code : VRCH2097 | Industry : Chemicals & Materials | Available Format :

|

Page : 200 |

3D Printing Materials Market – Analysis and Forecast (2025-2030)

Industry Insight by Material Type (polymers, metal and metal alloys, ceramics, and other printing materials), by End-User (automotive, consumer, healthcare, government and military, architecture, packaging, and others) and Geography (U.S., Canada, Germany, U.K., France, China, Japan, India, and Rest of the World)

Industry Overview

3D printing materials are materials used for 3D printing (additive manufacturing) and range from polymers like PLA and ABS, which are adaptable and simple to use, to metals like titanium and aluminum, which offer robustness for aerospace and automotive parts. Concrete-based building materials also perform well, allowing for quick development of architectural projects and houses. Medical implants require materials that are biocompatible, such as PEEK as the strength-to-weight ratios of carbon fiber-infused polymers are exceptionally high. Electronics and other specialized industries use ceramic materials, composites that include multiple constituents improve the qualities of the material. Manufacturing, prototyping, and design across industries are being revolutionized by using these varied materials for 3D printing.

Global 3D printing materials market was worth USD 1.0 billion in 2023 and is expected reach USD 5.82 billion by 2030 with a CAGR of 23.82% during the forecast period, i.e., 2025-2030. The growing demand for 3D printing materials is supported by the crucial role that 3D printing has played in transforming manufacturing techniques. Rapid prototyping using 3D printing is becoming more and more popular in industries such as automotive, electrical and electronics, because it enables quick design revisions and economical product development. Additionally, a variety of applications, from aerospace parts to medical implants, are catered to by the materials' diversity, which spans polymers, metals, ceramics, and even biocompatible compounds. The scope for customization and less material waste in 3D printing contribute to its widespread use. The demand for 3D printing materials is expected to increase as technology develops and material possibilities increase in the future.

Geographically, the market is expanding rapidly in North America, Europe, and the Asia Pacific, as a result of the presence of large companies and investment towards 3D printing; however, the market confronts constraints such as material compatibility, quality assurance, and lack of regulations. Overall, the 3D printing materials market offer potential prospects for market participants to develop and fulfill the growing needs of wide range of industries including automotive, aerospace, healthcare, electrical and electronics, and packaging.

3D printing materials market Segmentation

Insight by Material Type

Based on the material type, the global 3D printing materials market is segmented into polymers, metal and metal alloys, ceramics, and other printing materials. Polymer dominate the global 3D printing materials market due to their adaptability and simplicity. Polymers include a variety of alternatives, each suited for a particular use, such as PLA, ABS, PETG, PEEK, and TPU.

Polymers are used by several industries such as automotive, aerospace, and healthcare, for a range of applications due to their low melting points and compatibility with various 3D printing processes. Additionally, biodegradable polymers like PLA are in line with sustainability objectives. Their popularity is further supported by their affordability and capacity for producing intricate shapes. Polymers continue to be the material of choice for a wide variety of industries and applications, even if metals and ceramics have made space in the global 3D printing materials market in the recent years.

Insight by End-User

Based on the end-use industry, the global 3D printing materials market is segmented into automotive, consumer, healthcare, government and military, architecture, packaging, and others. Aerospace industry dominated the global 3D printing materials market in 2022 owing to stringent performance demands and complex geometries of aircraft components. 3D printing allows for lightweight, high-strength parts, reducing fuel consumption. Materials such as titanium, aluminum, and specialized composites cater to aerospace's unique requirements and 3D printing can manufacture any part in significantly less time than the conventional methods of manufacturing. Additionally, additive manufacturing enables rapid prototyping and customization, crucial in the fast-evolving aviation sector. These factors drive the extensive adoption of 3D printing materials, solidifying aerospace as a frontrunner in the global 3D printing materials market.

Global 3D printing materials market Report Coverage

|

Report Metric |

Details |

|

Historical Period |

2018–2023 |

|

Base Year Considered |

2024 |

|

Forecast Period |

2025 - 2030 |

|

Market Size in 2023 |

$1.00 Billion |

|

Revenue Forecast in 2030 |

$5.82 Billion |

|

Growth Rate |

CAGR 23.8% |

|

Segments Covered in the Report |

By Material Type and By End User |

|

Report Scope |

Market Trends, Drivers, and Restraints; Revenue Estimation and Forecast; Segmentation Analysis; Impact of COVID-19; Companies’ Strategic Developments; Market Share Analysis of Key Players; Company Profiling |

|

Regions Covered in the Report |

North America, Europe, Asia-Pacific, Middle East, and Rest of the World |

Industry Dynamics

3D printing materials market Growth Drivers

High investment in 3D printing

One of the factors driving the expansion of the 3D printing service sector is the high cost of 3D printing machinery. Companies looking for 3D printed parts have the option of purchasing the 3D printers or outsourcing to a service provider. Many choose to combine the two, reaping the advantages of having access to cutting-edge technology, lower investment risk, internal production capacity, and expert additive manufacturing knowledge. Companies needing a variety of products and services that they might not have the resources or knowledge to handle themselves outsource their requirements frequently.

Investing in 3D printing entails more than just acquiring a machine; it also includes materials, maintenance of printers, and software setup. Smaller businesses want to test 3D printing through services rather than making the significant investment in internal operations. Even Fortune 500 firms outsource 3D printing projects for prototypes and production runs, so service providers supplement in-house capabilities. These suppliers are essential partners for businesses wishing to use this technology since they have in-depth understanding of the market, process controls, and 3D printing proficiency.

Extensive demand from healthcare industry

The 3D printing materials market is growing as a result of the rapid uptake of 3D printing technology in the healthcare industry. This innovative technology is expected to revolutionize healthcare by satisfying the rising need for bespoke medical equipment. The creation of surgical guides, prosthetics, and patient-specific reproductions of bones, organs, and blood arteries all depend heavily on 3D software and services. Printing medical equipment is the primary application for powder bed fusion, a flexible process that works with materials like titanium and nylon.

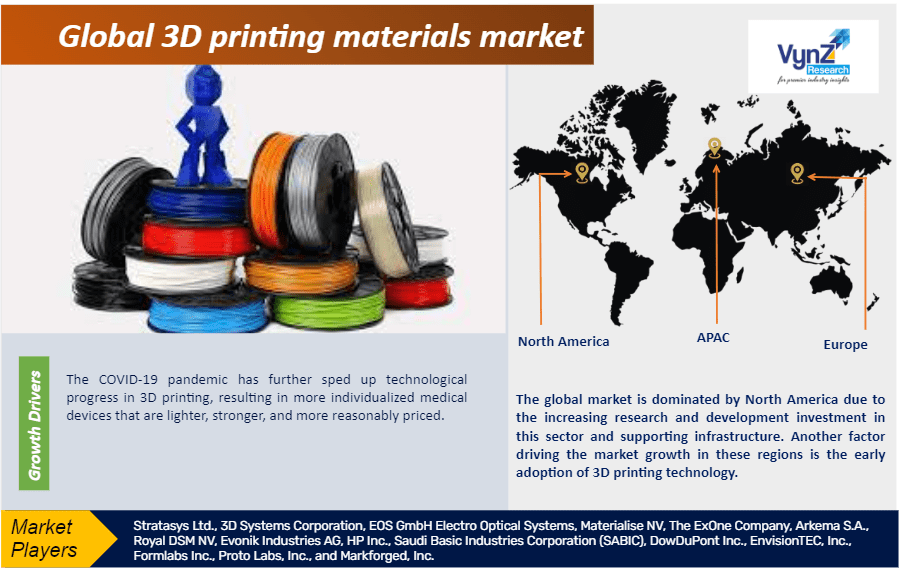

The COVID-19 pandemic has further sped up technological progress in 3D printing, resulting in more individualized medical devices that are lighter, stronger, and more reasonably priced. Businesses quickly shifted their use of additive manufacturing to the production of vital medical supplies such as ventilator parts and PPE kits and this highlighted how flexible and essential 3D printing is in healthcare. Iterative design and accurate, quick prototyping made possible by 3D printing technology ultimately result in safer, more useful goods. Additionally, it shows promise in cutting down on material waste and optimizing production procedures, underscoring its potential for environmentally friendly healthcare solutions.

3D printing materials market Challenge

Lack of regulations around 3D printing

The requirement for material standardization and quality assurance is a significant barrier for the global 3D printing materials market. With such a variety of materials available, it is essential to guarantee consistency in quality and compatibility with different 3D printing technologies. For accurate and high-quality prints, achieving homogeneity in material parameters, such as viscosity and melting points, is crucial.

Additionally, approved materials are required for safety and performance in sectors with strict regulatory requirements, such as aerospace and healthcare. To inspire confidence in the dependability and effectiveness of 3D printing materials, it is important to have industry-wide standards and strict testing procedures, which are not strictly imposed in the 3D printing industry at this moment. In order to maintain the growth and wide adoption of 3D printing and 3D printing materials across industries, it will be essential to overcome this challenge.

3D printing materials market Geographic Overview

-

North America

-

Europe

-

Asia Pacific (APAC)

-

Middle East and Africa (MEA)

-

Latin America

The global 3D printing materials market is segmented into North America, Europe, the Asia-Pacific, Latin America, and the Middle East and Africa region. The global market is dominated by North America due to the increasing research and development investment in this sector and supporting infrastructure. Another factor driving the market growth in these regions is the early adoption of 3D printing technology.

3D printing materials market Competitive Insight

Materialise is one of the largest players in the 3D printing materials market. Materialise is renowned for its knowledge and innovation, and a wide range of products and services designed specifically for sectors such as healthcare, aerospace, and the automotive industry. In line with the movement toward individualized and evidence-based care, their specialized medical division concentrates on clinical services and medical software. Pushing the limits of generating living organs for study and testing, Materialise is also at the forefront of bio-printing. Materialise is essential in improving the capabilities and uses of 3D printing materials because of its dedication to quality and in-depth knowledge of numerous sectors. Their efforts have a significant influence on how additive manufacturing will develop in the future.

Stratasys is a major player in the 3D printing materials market known for its cutting-edge approaches and materials. Stratasys serves a variety of industries, including aerospace, automotive, healthcare, and consumer goods, by providing a wide selection of high-quality materials. Their materials range from polymers to cutting-edge composites, enabling detailed and long-lasting prints. Because of its dedication to R&D, Stratasys has established itself as a market leader in 3D printing materials market, fostering innovation and empowering companies to scale new heights in additive manufacturing.

Recent Development by Key Players

In October 2023, Formlabs launched three healthcare-focused 3D printing materials - BioMed Elastic 50A Resin, BioMed Flex 80A Resin, and IBT Flex Resin. BioMed Elastic 50A Resin and BioMed Flex 80A Resin will be used 3D printing applications in healthcare as a cost-effective and fast alternative to traditional production methods, such as molding, for surgical models, medical devices, and more.

In October 2023, Evonik launched 2 separate grades of the ‘world’s first’ carbon fiber reinforced PEEK filament for 3D printed medical implants. VESTAKEEP iC4612 3DF and VESTAKEEP iC4620 3DF, grades of the carbon fiber reinforced PEEK feature 12% and 20% carbon fiber content respectively and can be processed in common extrusion-based 3D printing technologies such as fused filament fabrication (FFF).

Key Players Covered in the Report

Stratasys Ltd., 3D Systems Corporation, EOS GmbH Electro Optical Systems, Materialise NV, The ExOne Company, Arkema S.A., Royal DSM NV, Evonik Industries AG, HP Inc., Saudi Basic Industries Corporation (SABIC), DowDuPont Inc., EnvisionTEC, Inc., Formlabs Inc., Proto Labs, Inc., and Markforged, Inc.

The 3D printing materials market report offers a comprehensive market segmentation analysis along with an estimation for the forecast period 2025–2030.

Segments Covered in the Report

-

By Material Type

-

Polymers

-

Plastics

-

Acrylonitrile Butadiene Styrene (ABS)

-

Polylactic Acid (PLA)

-

Polyvinyl Alcohol Plastic (PVA)

-

Polycarbonate (PC)

-

Other plastics

-

-

Photopolymers

-

-

Metal and Metal Alloys

-

Titanium

-

Gold and silver

-

Copper and its alloys

-

Nickel and its alloys

-

Aluminum

-

Stainless steel

-

Other metals

-

Tungsten and its alloys

-

Cobalt-chrome alloys

-

-

-

Ceramics

-

Other Prinitng Materials

-

Wax

-

Concrete

-

Composites

-

Laywood

-

Laybrick

-

-

By End-Use Industry

-

Automotive Industry

-

Consumer Industry

-

Healthcare Industry

-

Government and Military Industry

-

Architecture Industry

-

Packaging Industry

-

Other End-use Industry

Region Covered in the Report

-

North America

-

U.S.

-

Canada

-

Mexico

-

Europe

-

Germany

-

U.K.

-

France

-

Italy

-

Spain

-

Russia

-

Rest of Europe

-

Asia-Pacific (APAC)

-

China

-

Japan

-

India

-

South Korea

-

Rest of Asia-Pacific

-

Middle East and Africa (MEA)

-

Saudi Arabia

-

U.A.E

-

South Africa

-

Rest of MEA

-

Latin America

-

Argentina

-

Brazil

-

Chile

-

Rest of Latin America

.png)

Source: VynZ Research

.png)

Source: VynZ Research

Frequently Asked Questions

Purchase Options

Latest Report

Research Methodology

- Desk Research / Pilot Interviews

- Build Market Size Model

- Research and Analysis

- Final Deliverabvle

Connect With Our Sales Team

- Toll-Free: 1 888 253 3960

- Phone: +91 9960 288 381

- Email: enquiry@vynzresearch.com

3D Printing Materials Market