| Status : Upcoming | Report Code : VRCH2049 | Industry : Chemicals & Materials | Available Format :

|

Global Shape Memory Alloys Market – Analysis and Forecast (2025-2030)

Industry Insights by Type (Nitinol, Copper-Based, Iron-Manganese Silicon), by End-User (Biomedical, Aerospace & Defense, Automotive, Consumer Electronics & Home Appliances)

Industry Overview

Shape memory alloys are a class of alloy which displays a thermal and mechanical memory effect. These are alloys that have memory. This material can be deformed at low temperature and can recover their original shape when heated. The shape memory alloys market is witnessing a good growth in the recent years and anticipated to witness the significant growth during the forecast period. This can be attributed to its increasing application such as adaptive structures, actuators, medical devices, heat detection devices, high temperature automotive, oil/gas down-hole, aeronautics, military, and others. However, currently, the applications of these materials are limited because of their low transformation temperatures.

Shape Memory Alloys Market Segmentation

Insight by Type

On the basis of type, the shape memory alloys market is classified into nitinol, copper-based, iron-manganese silicon, and others. Among all these, nitinol alloys category holds the largest share in the market and also expected to register the highest CAGR during the forecast period. This is attributed to their extensive use in the manufacturing of implantable medical devices, automotive actuators, surgical instruments, and others. Hence, the increasing of these materials is increasing in the medical, automotive, consumer electronics and other industries, contributing towards the market growth.

Insight by End-User

Based on end-user, the shape memory alloys market is segmented into biomedical, aerospace and defense, automotive, consumer electronics, home appliances, and others. The biomedical industry category is dominating the market by holding the largest market share, owing to the use of these materials in various applications which includes orthopedic screws and wires, dental archwires, cardiovascular & endoscopic stents, dental archwires, and other. However, along with biomedical industry, consumer electronics industry category is anticipated to witness the fastest growth in the market.

Shape Memory Alloys Market Report Coverage

|

Report Metric |

Details |

|

Historical Period |

2018–2023 |

|

Base Year Considered |

2024 |

|

Forecast Period |

2025 - 2030 |

|

Market Size in 2023 |

$xx.xx Billion |

|

Revenue Forecast in 2030 |

$xx.xx Billion |

|

Growth Rate |

CAGR xx.xx % |

|

Segments Covered in the Report |

By Type, and By End-User |

|

Report Scope |

Market Trends, Drivers, and Restraints; Revenue Estimation and Forecast; Segmentation Analysis; Impact of COVID-19; Companies’ Strategic Developments; Market Share Analysis of Key Players; Company Profiling |

|

Regions Covered in the Report |

North America, Europe, Asia-Pacific, Middle East, and Rest of the World |

Industry Dynamics

Shape Memory Alloys Market Growth Drivers

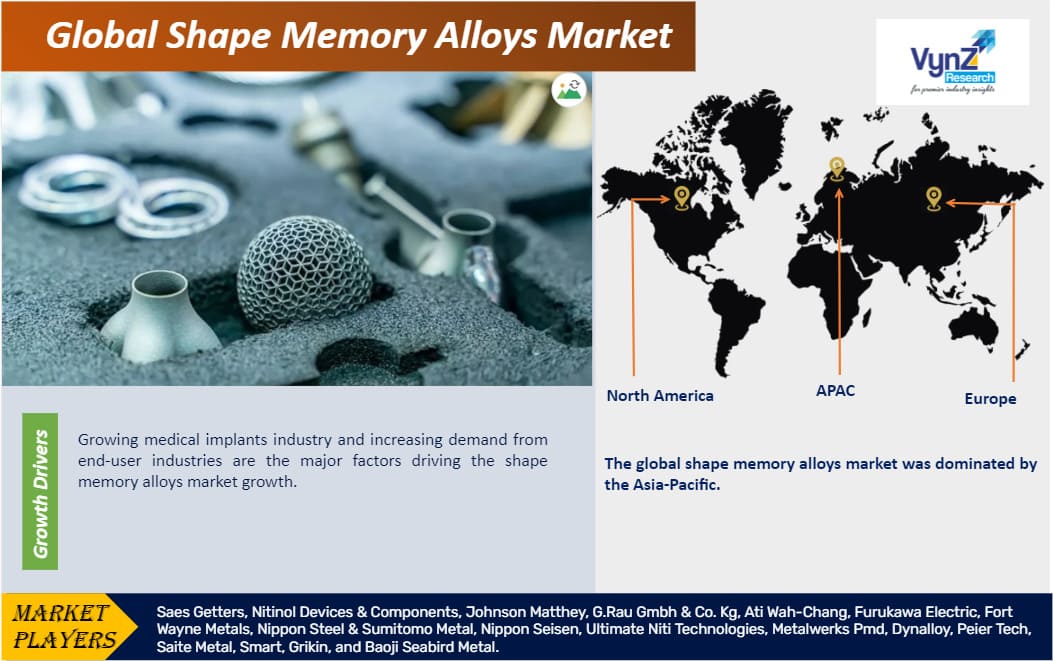

Growing medical implants industry and increasing demand from end-user industries are the major factors driving the shape memory alloys market growth. These materials provide various benefits to the users, for example, they provide high force that allows lightweight compact actuator designs, eliminates extraneous systems (hydraulic, pneumatic, and others), responds to temperature change that eliminated the need for electronics and sensors, enable simple, frictionless designs which require less maintenance, and others. All these benefits are contributing in the increasing demand of these materials in the various industries, resulting in the market growth. Also, they are ideal for large stroke, high force, and modest frequency response operations.

Shape Memory Alloys Market Challenges

High cost of raw material is the major challenge that can hinder the shape memory alloys market growth during the forecast period. There are only few industries which can afford the cost and research required to develop new markets such as medical industry. For instance, the price of Nitinol is tremendously high and the content extremely low. Manufacturers use it by the inch and not by the pound, which is among the major concern in the market.

Shape Memory Alloys Market Industry Ecosystem

Various companies are investing into the research and development of new alloys with higher transition temperatures and narrower temperature hysteresis to widen the application areas of these materials. The industry is facing major competition from established technologies such as direct-current motors.

Shape Memory Alloys Market Geographic Overview

Asia-Pacific shape memory alloys market is expected to register the highest CAGR in the market during the forecast period. This can be attributed to the increasing demand of these materials in the various industries including consumer electronics, biomedical, and others. Along with that, the major factors that are driving the market growth in the region are rapid economic expansion, rapid industrialization of countries such as India and China. Further, increasing manufacturing activities along with the region’s emergence as a cost-effective manufacturing hub is projected to drive the shape memory alloys market in the region.

Shape Memory Alloys Market Competitive Insight

Saes Getters shape memory alloys (SMA) offer a world of possibilities with their unique combination of size, shape, and geometry versatility. The Shape Memory Effect (SME) is activated by a change in the component’s lattice structure, transforming from martensite to austenite and resulting in a change in shape and mechanical properties. These materials are revolutionizing various industry verticals like automotive, medical, and electronics industries with their lightweight, energy-efficient, compact and noiseless electrical actuators.

Some of the key players operating in the global shape memory alloys industry are Saes Getters, Nitinol Devices & Components, Johnson Matthey, G.Rau Gmbh & Co. Kg, Ati Wah-Chang, Furukawa Electric, Fort Wayne Metals, Nippon Steel & Sumitomo Metal, Nippon Seisen, Ultimate Niti Technologies, Metalwerks Pmd, Dynalloy, Peier Tech, Saite Metal, Smart, Grikin, and Baoji Seabird Metal.

Recent Developments by Key Players

Fort Wayne Metals and Nexremity Solutions, Inc. collaborated to commercialize implants using Magnesium Alloy.

Johnson Matthey & KBR sign an alliance agreement to license Innovative Production Technology.

Frequently Asked Questions

Purchase Options

Latest Report

Research Methodology

- Desk Research / Pilot Interviews

- Build Market Size Model

- Research and Analysis

- Final Deliverabvle

Connect With Our Sales Team

- Toll-Free: 1 888 253 3960

- Phone: +91 9960 288 381

- Email: enquiry@vynzresearch.com

Shape Memory Alloys Market