| Status : Upcoming | Report Code : VRSME9027 | Industry : Semiconductor & Electronics | Available Format :

|

Global 3D Printing Market – Analysis and Forecast (2025 – 2030)

Industry Insights by Printer type (Industrial Printer and Desktop 3D Printers), by Material Type (Metals, Wax Plastics, Laywood, Ceramics, Paper and Bio-Compatible Material), by Industry Verticals (Healthcare, Automotive, Printed Electronics, Architecture & Construction, Consumer Products, Education, Aerospace & Defense, Jewellery, Energy, Industrial, Food & Culinary and Others), by Component (Hardware, Software and Services), by Application (Production, Prototyping, Proof of Concept and Others), by Technology (SLS, SLA, FDM, DMLS/SLM, DLP, Inkjet, Polyjet, Binder Jetting, multijet fusion, EBM, SDL, CLIP/CDLP and LOM Printing Categories) and by Geography (North America, Europe, Asia-Pacific, Middle East, and Rest of the World)

Industry Overview

The global 3D printing market is estimated at USD 18.5 billion in 2023. It is expected to grow to eventually reach USD 39.4 billion by 2030 during the forecast period at CAGR of around 17.8%.

3D printing implies the technology or manufacturing process that uses multiple layers to create a three-dimensional object from a given digital sample. Typically, this innovative technology is used to create customised prototypes during testing stages which helps significantly in reducing the cost of prototypes. It also reduces the time taken to make a prototype because it does not need much labour or skill.

Even a few years ago, the cost of using this technology was very high and therefore it was restricted to large organizations. However, with the advancements in technology, the cost was reduced due to the advent of desktop-based 3D printers. This made the technology more accessible to small and medium enterprises as well as home users.Typically mixed-material printers are being used extensively across several end-use verticals which is strengthening the 3D printing market, its applicability, and business on a global scale. The most common areas of application of the 3D printing technology are prototyping, modeling, and forging. In addition to that, the academic and technical training institutes are also implementing flash forge 3D printers.

All these factors typically enhance the growth prospects of the 3D printing market on a global scale.

Currently, 3D printers are increasingly used to manufacture customized prototypes during testing phases. The 3D printing technology helps the business organizations in creating prototype at lower costs, reduced time and do not require specific labor skill for developing a product thereby enhancing the growth of the 3D Printing Market across the globe.

3D Printing Market Segmentation

Insight by Printer Type

The global 3D printing market is divided into industrial 3D printers and desktop 3D printers according to their types. Out of these two segments, the desktop 3D printers segment is expected to grow at a much faster rate than the other during the forecast period. This is mainly because technological developments will allow for making new, innovative, and customized products for consumers.

Insight by Material Type

The global 3D printing market is also divided according to the type of material. These include metals, plastic, wax, lay wood, paper, polymer, ceramics, and bio-compatible materials. Among all these segments, the largest revenue is contributed by the plastic material segment. This is because it is the most commonly used and crucial material for 3D printing.

However, the metal sector is expected to account for more than half of the revenue share of the global 3D printing market. In this particular domain, the most commonly used 3D printing and the strongest procedure is the stainless steel domain in powdered for the sintering/melting/EBM processes.

On the other hand, the polymer section is expected to grow at a faster rate during the forecast period and contribute more in terms of revenue for materials, hardware, and 3D-printed parts sales. The early adopter of this printing technique is the medical field which now has a variety of applications and use cases ranging from human tissue replacement for pre-surgical preparation to 3D-printed surgical tips and tools. This is one of the most practical printing solutions to make ventilator valves, safety goggles, test swabs, protective face shields, and more.

Insight by Industry Verticals

The varied industry verticals split the global 3D printing market into healthcare, automotive, printed electronics, architecture & construction, consumer products, education, aerospace & defense, jewelry, energy, industrial, food & culinary, and others.

Out of all these segments, the aerospace & defense segment is expected to grow at a reasonably higher rate than the others due to the extensive use of this technology for developing products that require superior performance and quality at the time of development.

Insight by Components

The global 3D printing market is divided into hardware, software, and services sectors according to the components.

Out of these segments, the hardware sector dominates the global 3D printing market in terms of revenue contribution, which is expected to be 65% of the total amount. This is due to the increased importance of accelerated prototyping and use of innovative manufacturing practices.

In addition, rapid urbanization and industrialization along with the growing popularity of customer electronic devices have also pushed the hardware market further. It is also the result of the improving civil infrastructure and optimized labor costs that drives the expansion of the hardware sector as well.

The demand for hardware is also growing due to the growing practice by the leading players in the industry to improve their product investments and create novel procedures to meet the growing needs of several industrial verticals.

On the other hand, during the forecast period, the software sector is also expected to grow at a high CAGR being used extensively in developing products and parts that are supposed to be printed in diverse business verticals. The demand for software sector will also be segmented by the increased practice of scanning items and saving scanned pictures of articles during the prediction period, irrespective of their dimensions or size, to produce 3D prints of those products as and when required.

Insights by Application

There are different types of applications for 3D printing technology namely, production, prototyping, proof of concept, and others.

Out of all these segments, the prototyping sector rules the global 3D printing market in terms of revenue generation. It contributes more than 50% of the total revenue due to the extensive use of this procedure across a variety of industry verticals, such as aerospace, defense, automotive, and other industries. It is mainly used to design and develop precise components and parts. This helps the manufacturers to produce reliable and more effective finished products using the prototyping technique, helping this sector to dominate the market during the forecast period.

However, the functional part segment is also expected to grow at a faster rate during the projected period due to their higher precision and accuracy in developing critical systems and hardware.

As for the production segment, it will also grow at a reasonably high CAGR during the analysis period due to the growing affinity of the manufacturers to move from traditional manufacturing processes to more advanced procedures. In addition to that, the growing use of this technology to create complex and lkow-volume parts will also propel the growth of this sector during the forecast period.

Insights by Technology

The diverse technologies used in 3D printing divide this market into SLS, SLA, FDM, DMLS/SLM, DLP, inkjet, polyjet, binder jetting, multijet fusion, EBM, SDL, CLIP/CDLP, and LOM printing categories.

Out of all these segments, the Fused Deposition Modeling (FDM) segment will contribute a larger share of the market during the forecast period due to higher adoption across several 3DP procedures.

On the other hand, the DLP, inkjet printing, and EBM segments are also expected to witness faster growth during the projected period due to their greater applicability across a variety of specialized additive manufacturing processes. A wider adoption opportunity is created due to the growing acceptance of these novelties in the defense, aerospace, automotive, and healthcare sectors to drive its market growth.

The Direct Metal Laser sintering (DMLS/SLM) segment is expected to grow in the forecast period significantly at a high CAGR due to its ability to produce high-quality metal components for different manufacturing industries that need to create complex metal geometries of extremely small size.

The Selective Laser Sintering (SLS) segment will also grow significantly in the projected period due to its growing popularity and use in the consumer goods sector having a wide range of application.

Global 3D Printing Market Report Coverage

|

Report Metric |

Details |

|

Historical Period |

2018 - 2023 |

|

Base Year Considered |

2024 |

|

Forecast Period |

2025 - 2030 |

|

Market Size in 2024 |

U.S.D. 18.5 Billion |

|

Revenue Forecast in 2030 |

U.S.D. 39.4 Billion |

|

Growth Rate |

17.8% |

|

Segments Covered in the Report |

By Printer, By Material Type, By Industry vertical, By Components, By Application and By Technology |

|

Report Scope |

Market Trends, Drivers, and Restraints; Revenue Estimation and Forecast; Segmentation Analysis; Impact of COVID-19; Companies’ Strategic Developments; Market Share Analysis of Key Players; Company Profiling |

|

Regions Covered in the Report |

North America, Europe, Asia-Pacific, Middle East, and Rest of the World |

Industry Dynamics

3D Printing Industry Trends

Increasing demand for latest technology among various business enterprises to develop more affordable and accessible alternatives in small and medium enterprises is the key trend observed in the growth of 3D printing market globally. The technology is transforming the traditional functioning of the business and redefining the business process in several organizations. 3D printing allows the manufacturing of a 3D object to form a computer-driven digital process. The additive printing process use varies in accordance to the materials and budget acquired for the functioning of technology. The adoption of 3D printing is increasing in engineering, architecture, medical, industrial design and construction industry.

3D Printing Market Growth Drivers

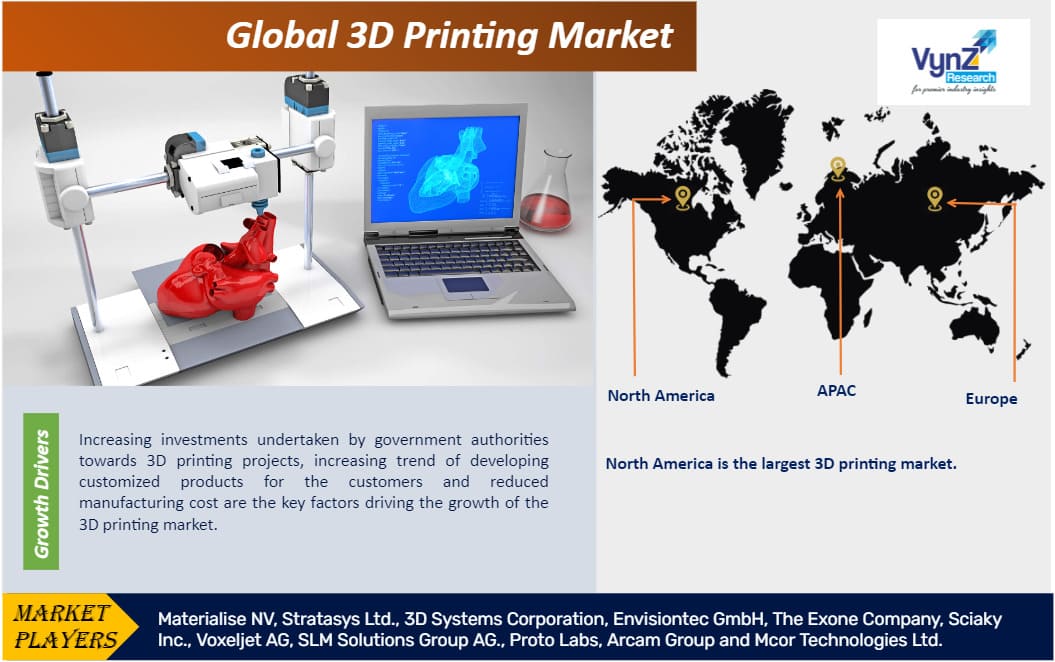

Increasing investments undertaken by government authorities towards 3D printing projects, increasing trend of developing customized products for the customers and reduced manufacturing cost are the key factors driving the growth of the 3D printing market. The potential of 3D printing technology to enhance the manufacturing and supply chain management process of the business organization is the key factor driving the growth of the 3D printing market. 3D printing technology helps in providing ease to manufacturing process of the organizations and provides several benefits to the traditional production techniques.

Furthermore, it helps the organizations to produce different variety of products with the help of single 3D printer. This helps the manufacturers in reducing the various numbers of steps involved in a production chain and helps the enterprises to leverage production concepts and on-demand concepts. 3D printing thus enables the overall simplification of the management and supply chain process thereby providing significant economic savings for the organization on production and logistics costs. Moreover, the limited designing tools offered by 3D printing technology is the major restraint observed for the growth of the 3D printing market.

3D Printing Market Challenges

The high costs of materials and restraint pertaining to the size of the product are the major factors that are hampering the growth of 3D printing market across the globe. Moreover, lack of acceptance of such technology and limited designing tools offered by 3D printing technology is the major restraint observed for the growth of global 3D printing market.

3D Printing Industry Ecosystem

Globally industry players in 3D printing market are leveraging market growth through the development of innovative solutions. The vendors of 3D printing technology are providing various solutions to users such as customization, cost efficiencies, developing new products and are further improving productivity with the help of latest technologies.

3D Printing Market Geographic Overview

Geographically, North America is the largest 3D printing market in since the region is constantly revamping their technology and increasingly using 3D printing technology in healthcare and aerospace and defense domain. Furthermore, increasing demand for customized products by the customers and need for reducing operational costs by several business organizations is driving the demand for 3D printing in this region.

Moreover, 3D printing market in Asia-Pacific is expected to witness the fastest growth due to the availability of informed consumers and the increasing demand for customized products from the end-users. 3D printing technology is enabling business enterprises in this region for improving product evolution, customer relationships and business growth by delivering products in a timely and speedy manner. Additionally, this technology is helping the suppliers in reducing the cost and time of their manufacturing and logistics process. Moreover, the adoption of 3D printing by healthcare domain is enhancing the growth of 3D printing market in this region.

3D Printing Market Competitive Insight

Key players in the 3D Printing Market are investing heavily towards improvising the quality of product and developing the latest technologies that is further strengthening their position in the market. Moreover, local vendors are developing new products to develop cost efficiencies in their business processes thereby extending the rivalry in the market to certain. Some of the major players in the 3D printing market include Materialise NV, Stratasys Ltd., 3D Systems Corporation, Envisiontec GmbH, The Exone Company, Sciaky Inc., Voxeljet AG, SLM Solutions Group AG., Proto Labs, Arcam Group and Mcor Technologies Ltd.

Recent Developments by Key Players

Materialise (a 3D printing company) has launched a personalised temporomandibular joint (TMJ) treatment, Total Arthroplasty System. This systemincludes implants, guides, and digital planning which is designed to treat patients for total temporomandibular joint (TMJ) arthroplasty. The TMJ, the joint where the skull and jawbone meet, plays a crucial role in the opening and closing of the jaw.

Stratasys Ltd. (a leader in polymer 3D printing solutions) has collaborated with Select Additive Technologies (a division of Morris Group, Inc.). This collaboration positions Stratasys as the sole provider of polymer 3D printing technologies to Select Additive's customer base across the United States. This partnership focus to facilitate the integration of additive manufacturing into the production strategies of its customers. This shall address challenges such as supply chain optimization, cost reduction and carbon footprint minimization.

.png)

Frequently Asked Questions

Purchase Options

Latest Report

Research Methodology

- Desk Research / Pilot Interviews

- Build Market Size Model

- Research and Analysis

- Final Deliverabvle

Connect With Our Sales Team

- Toll-Free: 1 888 253 3960

- Phone: +91 9960 288 381

- Email: enquiry@vynzresearch.com

3D Printing Market